Joining forces – how The Nexus promises to enhance CEA production

AGRI-TECH Innovation Centre CHAP has revealed conceptual plans for a project that tackles key challenges in controlled environment agriculture (CEA), to unlock its potential and help supply the UK with nutritious, sustainable, and affordable produce.

The solution is based on a business case for ‘The Nexus’, a proposed framework and network for partnership and collaborative innovation between the energy, water and food industries, focused on CEA food production across both greenhouse and vertical farming systems.

Now CHAP (Crop Health and Protection) seeks industry partners and interested collaborators to help make the outlined solution a reality.

Head of Marketing and Communications, Janine Adamson, said: “Through CHAP’s New Innovations Programme, the team brought together a collective of specialists and experienced industry voices to design a strategic business case that will combat the present gap in the market.

“During the process, stakeholders addressed the barriers for further expansion of controlled environment agriculture in the UK. A result of this process is a business case based on the government-endorsed Five Case Business Model – the Energy and Water Nexus for Controlled Food Production.”

Current barriers

Faye Tomson, Director of District Eating, joined CHAP in the programme. Reflecting on current industry barriers, she said: “According to a recent report, the total estimated waste heat from UK industry and electricity generation amounts to approximately 350,000 GWh/yr. There is great potential for this waste heat and waste CO2 to be utilised to supply protected horticulture production and support emissions reductions of as much as 70% against a fossil fuel gas business as usual scenario on a project by project basis.

“At District Eating we’ve been successful in mapping multiple sources of waste heat and CO2 across England, suitable for large-scale commercial greenhouses. With plenty of waste heat and CO2 across the country, the CEA sector has to think big and find ways to effectively cooperate.

“What we found to be key barriers for scaling up in the sector are stakeholders working together and sharing risks, such as infrastructure development which can cost millions of pounds. Going forward it is essential to find solutions around risk mitigation, cost sharing and building synergistic relationships.”

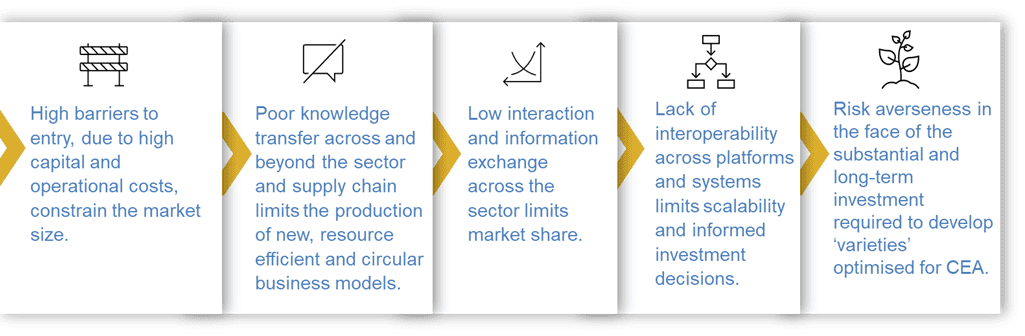

Furthermore, stakeholders from the New Innovations Programme identified the below key barriers: