“Robotics and automation have markedly become more prominent in our food production system, mainly in pre- and post-production. Progress in AI has led to a sharp rise in the emergence of novel technologies, complementing a shift in consciousness about the need to increase resilience in food production systems by preserving natural resources and enhancing environment sustainability. They promise to mitigate the many challenges faced by the sector – productivity, resilience, resource-efficiency, environmental sustainability, labour gap – to reach food security.

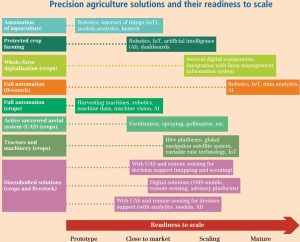

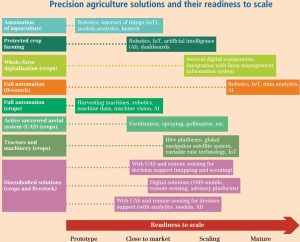

A recent Food and Agriculture Organisation of the United Nations (FAO) report on the main drivers for leveraging automation in agriculture highlights that though current applications are diverse, most are still in prototype phase; only few – mainly autonomous crop robots – have reached commercialised stage.

FAO, 2022

What does the future hold for CEA?

The CEA sector has a well-established interest in digital robotics and automation. Current innovation trends focus on the high potential of data-driven growing to alleviate global food systems challenges, and on barriers shared by the horticulture sector such as labour sourcing and affordability.

At present, many pre-and post-harvest operational tasks in greenhouses and total CEA can be automated, borrowing from processes used in manufacturing industries. Moreover, robotic platforms and autonomous ground vehicles have also emerged to assist with harvesting. Nonetheless, automation of harvest activities is limited in the fresh produce industry – with most solutions at R&D or pilot scale. A mixture of challenges such as scalability, demonstrating real-world solutions and replicating the intricate movements of the human hand, stagger the pace of adoption and implementation.

Leading role for the UK

A recent study led by CHAP and UK Urban AgriTech, UKUAT, outlined that the UK could have a leading role in both ‘robot farms’ – with companies such as Intelligent Growth Solutions and Vertical Future already establishing themselves as leaders in whole-farm integrated systems; and ‘farm robots’ – with companies such as Dogtooth, Antobot, or Saga Robotics either commercialising or receiving grant investment to develop harvesting solutions.

Pairing refined sensors and climate controls with advanced software and AI will play a crucial role in achieving autonomous monitoring and forecasting in CEA. UK-based companies in this space include TerraPrima Group, who focus on low-cost IoT-sensing combined with AI and machine learning; Gardin and Fotenix, both developing optical phenotyping.

Achieving autonomy

For the next generation of robots to become truly ‘autonomous’, their ability to learn and adapt on a continuous basis will be essential. This will require the integration of multiple technologies – including real-time sensors; sophisticated software and true AI; machine learning and computer vision – all powered by big data.

Achieving such progress would not only enable robots to perform tasks they were trained for, but also improve precision, independent decision-making, responsiveness, to name a few. This, in turn, could lead to independent operations management, as well as robot-human collaboration.

Can technology alone help revolutionise the sector?

Labour is a key requirement for fresh produce harvest – it accounts for 20-50% of most crops’ budgets. Yet, the sector’s fragile reliance on seasonal workforce caused by the labour gap has become more apparent during the recent pandemic and the end of free movement between the UK and Europe.

An independent report on Automation in horticulture, Defra, 2022, points to horticultural diversity as a major challenge to the development, scalability and adoption of digital agri-robotic solutions in the sector. The report projects that because of it, some tasks and crops may never be automated.

The technical challenges caused by horticultural diversity explains why many start-ups have circumvented the scalability challenge and increased the addressable market, a requirement for investors, by focusing their solutions on ‘common’ tasks, i.e. in pre-harvest and harvest-assist activities.

The recommendations in this report focus on ways to create an enabling environment to accelerate robotics development and on-farm adoption. One recommendation outlines how “technology alone is not a solution” and that there is a “need to provide the necessary infrastructure, funding, guidance and regulations to support this sectoral revolution”. Equally, the “role of government in creating an enabling environment to facilitate adoption of suitable, adapted automation solutions” is also echoed by the FAO report.”

What’s next?

In January, Defra launched a new funding competition, part of its Farming Innovation Programme, to support automation innovation to help the horticulture sector address key issues.

The Farming Futures: automation and robotics funding competition offers up to £12.5 million for collaborative projects.

Working with CHAP

If you are interested in discussing your project idea and/or how CHAP expertise and capabilities can help you develop your solution, please get in touch at enquiries@chap-solutions.co.uk.

Please note, the opinions expressed in this article are the author’s own and do not necessarily reflect the views or opinions of CHAP.